Manufacturing Capabilities

Advanced fabrication technologies and material sourcing for high-performance applications.

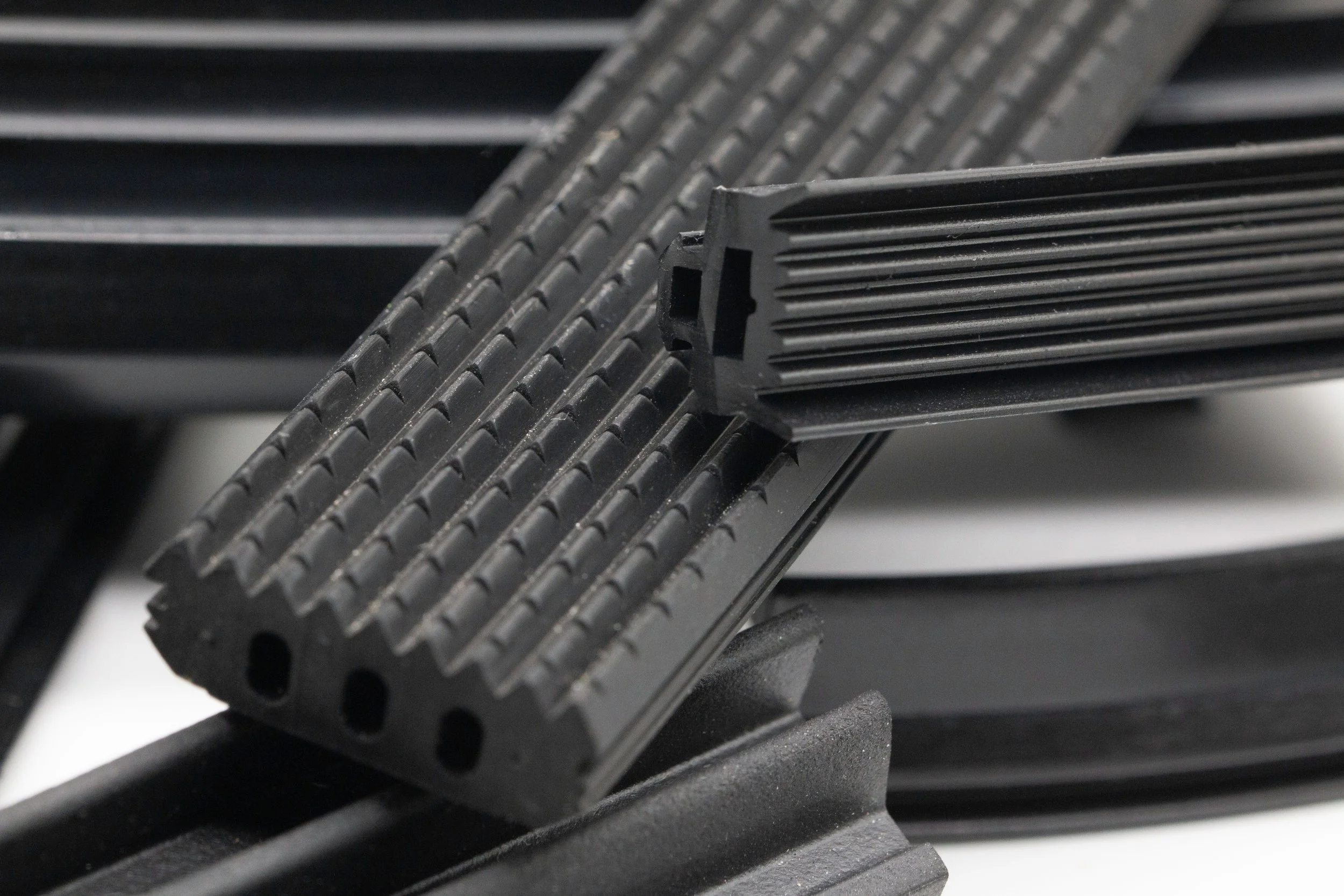

Rubber Molding

Molded rubber gaskets are precision-engineered sealing solutions. Created by injecting liquid rubber into a mold at high pressure, ensuring high precision for mass production.

Rubber Extruding

A manufacturing process where raw rubber material is transformed into a continuous profile of a specific shape. Ideal for creating custom sealing profiles for complex machinery.

Rubber Vulcanizing

The process for joining rubber profiles and creating gaskets. It involves heat, adhesive, and pressure to bond two ends of rubber together, resulting in continuous and solid gaskets.

Custom Die Cutting

Produced using a custom-designed tool with sharp edges to cut materials into specific shapes and sizes. Highly valued for accuracy, ensuring every gasket meets exact specifications.

Digital Knife Cutting

An innovative approach allowing for rapid prototyping and production. It quickly adapts to design changes and does not require custom dies, reducing both time and cost.

Global Sourcing

Strategic partnerships with the world's leading manufacturers (Teadit, Durlon, Flexitallic) to ensure access to the highest quality materials for any application.